In the intricate world of plumbing and HVAC devices, the enlargement tank typically operates at the rear of the scenes, diligently controlling stress fluctuations to safeguard all the infrastructure. While seemingly simple, its job is critical, and its longevity directly impacts procedure performance and routine maintenance charges. Have you ever at any time regarded as what truly makes an expansion tank endure the exam of your time? Beyond the Original price tag tag, the legitimate benefit lies in its ability to perform reliably, year after yr. From materials range to design and style criteria and proper upkeep tactics, we are going to uncover the tricks to maximizing the existence within your enlargement tanks.as being a filter tank manufacturer, we have an understanding of the value of high-top quality components and precision engineering in extending the lifespan of essential parts like growth tanks. no matter whether you’re an engineer, contractor, or facility manager, this detailed information will deliver important insights on maximizing method general performance and reducing extensive-term operational costs.

Table of contents:

the muse: content collection and Corrosion Resistance

style and design issues: Structural Integrity and Internal Components

The artwork of Manufacturing: Precision and excellent Handle

Environmental variables: being familiar with the working situations

the value of routine maintenance: Proactive ways for Longevity

criteria and Certification: guaranteeing Compliance and Quality

the inspiration: substance variety and Corrosion Resistance

The resources used in the development of an growth tank are the very first line of defense against premature failure. The selection method isn't pretty much Expense; It really is about matching the material to the precise working surroundings and also the fluid it is going to incorporate. Let's take a look at the important elements:

Tank human body product:

chrome steel Grades: The Gold conventional: chrome steel, especially grades like 304, 316, and duplex stainless-steel, is usually the popular choice for enlargement tanks because of its inherent corrosion resistance. Every single quality offers different amounts of safety against particular corrosive brokers. As an illustration, 316 chrome steel consists of molybdenum, which reinforces its resistance to chlorides, making it ideal for coastal environments or techniques employing taken care of h2o. Understanding the particular h2o chemistry within your program is crucial for choosing the right chrome steel quality.

Carbon Steel with protecting Coatings: a price-successful substitute: Carbon metal can be quite a viable option if paired with a robust protective coating. The efficiency of the approach hinges on the standard and software with the coating. Epoxy resins and polyurethane coatings are generally utilised, but their very long-term efficiency depends upon factors like coating thickness, adhesion into the metal surface, and resistance to abrasion and chemical degradation. frequent inspection and upkeep of the coating are essential to avoid corrosion from using maintain.

Lined Tanks: an additional Layer of Protection: For highly corrosive fluids or Intense running conditions, growth tanks with inner linings present an additional layer of safety. products like rubber, PTFE (Teflon), or specialised polymers can produce a barrier concerning the fluid along with the tank's steel framework, protecting against corrosion and increasing the tank's lifespan. The choice of lining content have to be thoroughly matched to the particular fluid being taken care of.

The Integrity of Welds:

Weld top quality: a series is just as Strong as Its Weakest website link: the standard of the welds is paramount. Weak or improperly executed welds can become factors of failure, bringing about leaks or maybe catastrophic rupture. things like welding method, filler materials assortment, along with the ability on the welder all contribute to weld integrity.

Non-damaging screening (NDT): making certain Hidden Flaws are Detected: NDT methods, which include radiographic testing (X-rays), ultrasonic testing, and magnetic particle testing, are essential for detecting concealed flaws in welds. These tests can expose cracks, porosity, as well as other imperfections that could compromise the tank's structural integrity. utilizing a demanding NDT software is often a critical financial commitment in long-phrase reliability.

Sealing and Fastening:

Seal elements: protecting against Leaks and retaining Pressure: The selection of seal components, which include O-rings and gaskets, is important for preventing leaks. The seal materials needs to be appropriate Together with the fluid getting managed and capable of withstanding the operating temperature and pressure. Regular substitute of seals, as Portion of a preventative maintenance system, is essential for preserving method integrity.

Fasteners and Connections: Preventing Corrosion-Induced Failure: The materials employed for fasteners, for instance bolts and screws, will have to even be corrosion-resistant. Stainless steel fasteners in many cases are chosen, specifically in outside or humid environments. appropriate torqueing of fasteners can also be crucial to be sure a safe link and stop loosening eventually.

design and style Matters: Structural Integrity and inner factors

over and above materials collection, the design of the expansion tank plays a essential job in its lifespan and longevity. A perfectly-developed tank minimizes stress, helps prevent corrosion, and makes certain the reliable functionality of interior components.

Structural design and style: reducing worry and exhaustion:

tension focus: figuring out and Mitigating Weak factors: Sharp corners, abrupt alterations in geometry, and improperly created supports can create parts of significant stress focus. These spots are prone to exhaustion failure, especially under cyclical tension loading. Finite component Evaluation (FEA) can be employed to recognize and mitigate worry concentrations in the design and style phase.

Thickness Calculations: Ensuring enough power: The thickness with the tank partitions and conclude caps need to be diligently calculated to face up to the most functioning pressure with an enough security margin. These calculations have to keep in mind the material's tensile toughness, generate toughness, and corrosion allowance.

assist buildings: more info delivering Stability and Load Distribution: The assist framework has to be robust sufficient to assist the load with the tank and its contents, as well as any exterior loads, such as wind or seismic forces. The aid design should also lessen pressure over the tank partitions.

inside style: Optimizing move and blocking Corrosion:

Flow Baffles: Preventing Stagnation and Sediment Create-Up: in certain purposes, movement baffles are used to direct the move of fluid within the tank, stopping stagnation along with the buildup of sediment. This is particularly significant in systems where the fluid is made up of particulate make any difference.

Diaphragms and Bladders: the guts on the Tank's operate: Expansion tanks often integrate diaphragms or bladders to independent the h2o and air cushions. The material and design of these parts are critical for their longevity. they have to be proof against the fluid being managed, along with the cyclical anxiety of enlargement and contraction. common inspection and substitute of diaphragms and bladders will often be important.

area therapy: improving Corrosion Resistance:

Blasting and Cleaning: getting ready the floor for defense: floor preparing, such as sandblasting or shot peening, is essential for developing a clear and textured floor that promotes the adhesion of protective coatings.

Passivation: maximizing the Corrosion Resistance of Stainless Steel: Passivation is often a chemical remedy that improves the corrosion resistance of stainless-steel by forming a skinny, protective oxide layer on the surface.

The artwork of Manufacturing: Precision and good quality Command

The production approach is where by the design ideas are introduced to lifestyle. Precision, high quality Regulate, and adherence to field requirements are paramount for making sure the very long-expression reliability of enlargement tanks.

content slicing: Precision and precision:

Precise chopping: Minimizing Waste and making sure healthy: correct substance cutting is essential for reducing squander and making certain that the tank elements match together appropriately. Personal computer-managed cutting machines can obtain significant levels of precision.

Forming strategies: Shaping the Tank with Precision:

Cold Spinning and incredibly hot Spinning: Shaping the Tank with Manage: chilly spinning and sizzling spinning are popular strategies for forming the tank's finish caps. These processes should be meticulously managed to make certain uniform thickness and stay clear of tension concentrations.

Welding approaches: generating sturdy and reputable Joints:

GTAW and SMAW: becoming a member of supplies with ability: gasoline tungsten arc welding (GTAW) and shielded metallic arc welding (SMAW) are frequent welding methods Utilized in the producing of enlargement tanks. the selection of welding technique will depend on the resources currently being joined and the specified weld top quality.

warmth Treatment: Relieving strain and boosting Strength:

put up-Weld Heat cure: minimizing Residual Stress: put up-weld warmth therapy is commonly employed To ease residual stresses in the weld joints, strengthening the tank's Total toughness and resistance to fatigue failure.

Environmental variables: knowledge the functioning Conditions

The ecosystem in which an enlargement tank operates can considerably impact its lifespan. Understanding these things and getting acceptable safety measures is important for maximizing longevity.

Temperature Extremes: Impact on components and Seals:

higher Temperature Degradation: picking out Materials for Heat Resistance: superior temperatures can accelerate corrosion and degrade the Qualities of products, specifically seals and diaphragms. choosing resources which can be rated with the running temperature is critical.

Low Temperature Embrittlement: protecting against Cracking in chilly Climates: lower temperatures may cause some supplies to be brittle, expanding the chance of cracking. This is particularly vital in cold climates.

force Fluctuations: Fatigue and Stress on Components:

Cyclical Loading: planning for exhaustion Resistance: Cyclical force fluctuations may cause exhaustion failure, particularly in areas of high anxiety focus. building the tank to resist the predicted pressure cycles is crucial.

Fluid Composition: Compatibility and Corrosion Resistance:

Corrosive Fluids: deciding upon Corrosion-Resistant products: The composition on the fluid remaining managed might have a significant impact on the tank's lifespan. Corrosive fluids can assault the tank components, bringing about leaks or failure. picking products that happen to be appropriate with the fluid is crucial.

External surroundings: defense from the Elements:

Outdoor defense: stopping UV Degradation and Corrosion: outside publicity can accelerate corrosion and degrade the Qualities of components, notably plastics and coatings. shielding the tank from The weather having a weatherproof enclosure is usually recommended.

the necessity of Maintenance: Proactive methods for Longevity

normal routine maintenance is important for ensuring the prolonged-phrase trustworthiness of enlargement tanks. Proactive steps can identify likely troubles early and forestall high priced failures.

Regular Inspections: figuring out Potential difficulties Early:

Visual Inspection: examining for Corrosion and harm: Regular visual inspections can recognize signs of corrosion, leaks, and Actual physical injury.

Pressure screening: Verifying Tank Integrity: Periodic pressure testing can validate the tank's integrity and establish any leaks.

Cleaning and Flushing: getting rid of Sediment and particles:

Sediment removing: protecting against Corrosion and Clogging: Sediment and debris can accumulate from the tank, resulting in corrosion and clogging. Regular cleansing and flushing can protect against these issues.

Replacing Worn Components: protecting against Failure:

Seal and Diaphragm Replacement: retaining process Integrity: Seals and diaphragms are matter to have on and tear and will get replaced periodically as part of a preventative routine maintenance application.

exterior Coating upkeep: preserving towards Corrosion:

Coating Inspection and maintenance: protecting against Corrosion distribute: frequent inspection and restore on the exterior coating can prevent corrosion from spreading and compromising the tank's structural integrity.

expectations and Certification: guaranteeing Compliance and good quality

Adhering to market benchmarks and getting certifications are crucial for making sure the quality and protection of enlargement tanks.

style and design and Manufacturing specifications: Compliance with market Norms:

ASME and PED: Meeting Global specifications: Compliance with market requirements, such as ASME (American Society of Mechanical Engineers) and PED (stress gear Directive), ensures that the tank is created and produced to meet demanding safety and effectiveness requirements.

3rd-bash Certifications: Verifying excellent and security:

CE and UL: Independent Verification of functionality: Third-party certifications, which include CE (Conformité Européenne) and UL (Underwriters Laboratories), give independent verification from the tank's excellent and safety.

The lifespan and longevity of growth tanks are multifaceted, determined by a mix of product choices, design and style things to consider, producing high quality, environmental factors, and diligent routine maintenance. By comprehending these key elements and utilizing greatest tactics, engineers, contractors, and facility managers can considerably increase the daily life of their growth tanks, minimize operational prices, and ensure the reputable performance of their devices. for the people seeking responsible and sturdy expansion tanks created to exacting standards, look at exploring possibilities from reputable suppliers like IWM, noted for their dedication to excellent and innovation in strain vessel know-how. Their filter tank and filter tank company history makes certain a amount of experience you could have faith in.

Jennifer Love Hewitt Then & Now!

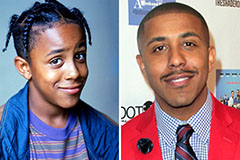

Jennifer Love Hewitt Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Seth Green Then & Now!

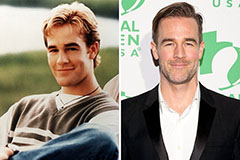

Seth Green Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now!